Water Ring Vacuum Pumps

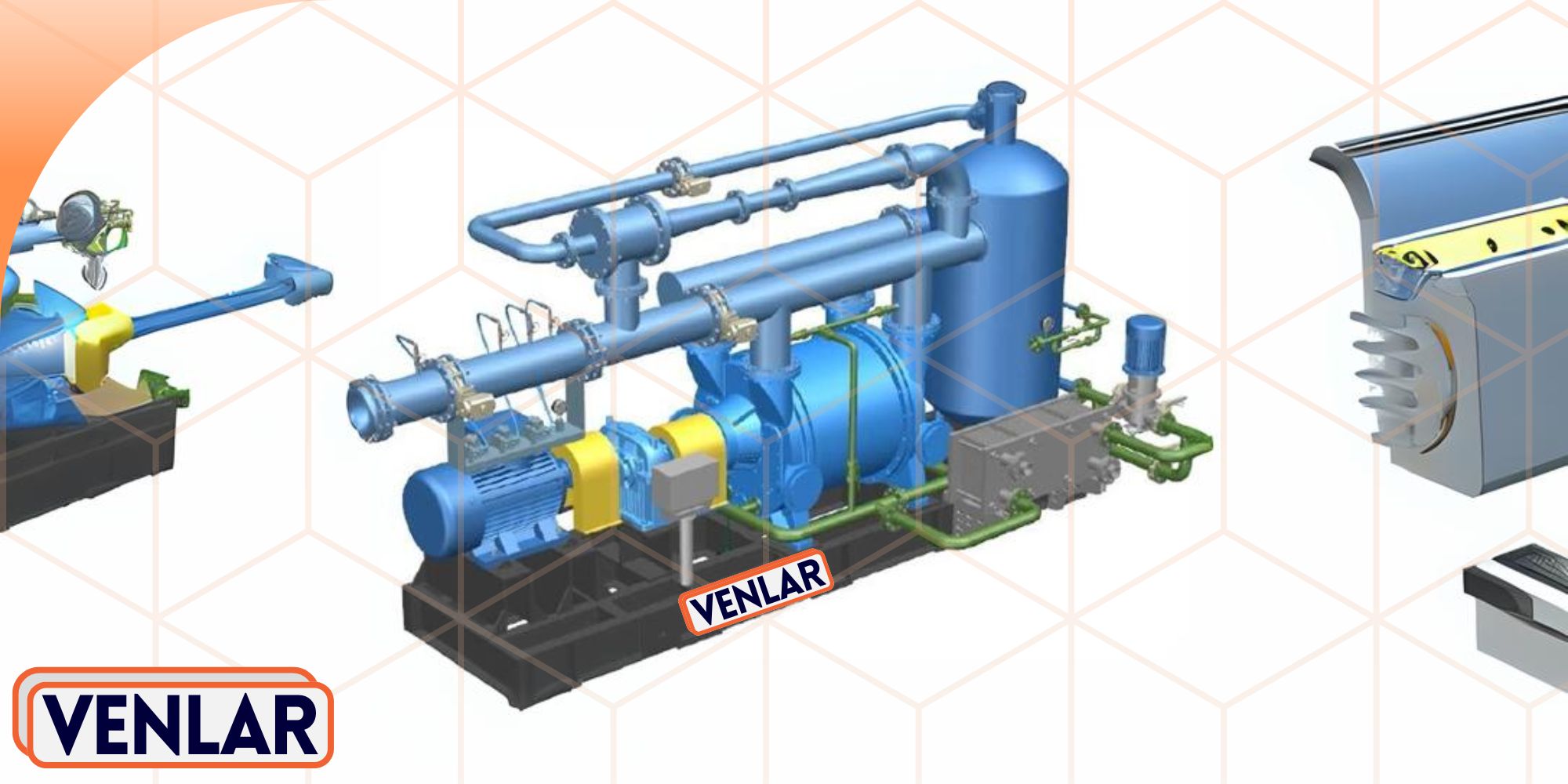

Venlar Corporation’s Single & Two Stage Liquid Ring Vacuum Pumping Systems provide an optimal solution for a wide range of rough vacuum applications in the chemical and allied process industries. Engineered for continuous operation at low pressure, these systems deliver high efficiency and reliability.

Technology

Our liquid ring vacuum pumps utilize a rotating impeller within a casing partially filled with liquid, typically water, which forms a ring that seals and compresses gases. This technology ensures robust performance and low maintenance, making it ideal for demanding industrial environments.

Description

Venlar’s Liquid Ring Vacuum Pumps are designed to handle tough applications with ease. Available in both single and two-stage configurations, these pumps are capable of achieving high vacuum levels and are suitable for continuous operation. The two-stage systems are particularly effective in applications requiring lower pressure and higher vacuum.

Customization Options

KEY Features

APPLICATIONS

Our liquid ring vacuum pumps are versatile and find uses across various industries, including:

Why Choose Venlar Corporation?

At Venlar Corporation, we prioritize quality and performance. Our liquid ring vacuum pumps are tested rigorously to ensure they meet the highest standards of reliability and efficiency. With a focus on customer satisfaction, we offer customizable solutions tailored to meet specific process requirements.

Contact Us

Explore the potential of Venlar Corporation's Single & Two Stage Liquid Ring Vacuum Pumps for your industrial applications. Contact us today to learn more about our products, request a quote, or schedule a consultation with our experts.