Advanced Vacuum Solutions for Modern Industries

Dry screw vacuum pumps are among the latest innovations in the vacuum technology industry. Designed with an eco-friendly "no oil, no water" principle, these pumps are ideal for applications that prioritize environmental sustainability. With a wide range of models and configurations, they cater to the diverse needs of various industrial processes.

Technology

Our dry screw vacuum pumps utilize a unique screw profile engineering that ensures efficient and reliable operation. The pumps operate by rotating a pair of screws that effectively admit gases from the inlet into the pump chamber. The gases are then compressed through the screw’s swept volume towards the discharge, ensuring optimal performance without the need for lubricants or operating fluids.

Description

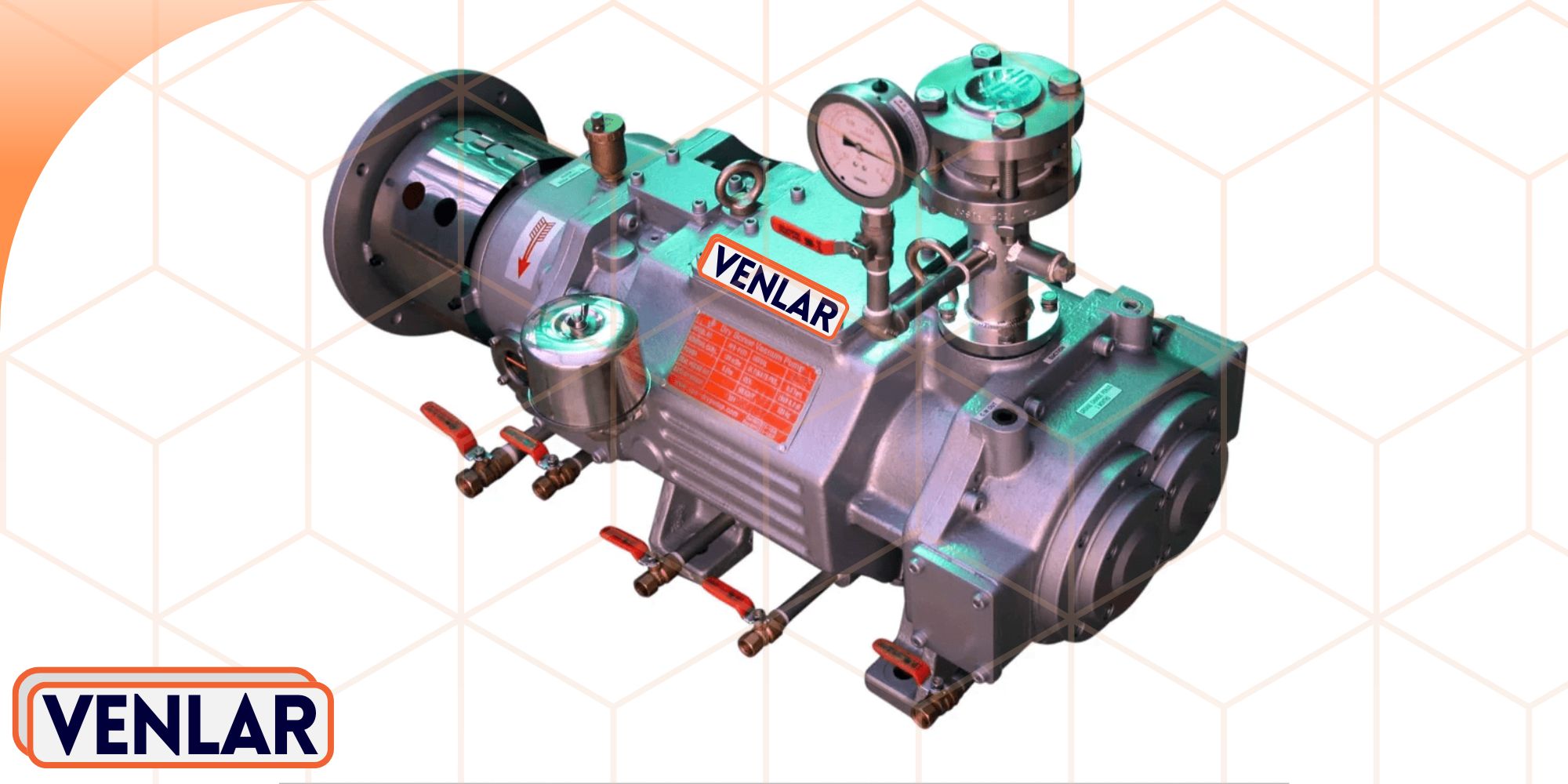

Dry screw vacuum pumps from Venlar Corporation are engineered to meet the demands of a wide range of chemical and industrial processes. These pumps are highly efficient, providing a reliable solution for applications requiring clean and contamination-free vacuum environments. Their design allows for seamless integration with other vacuum machines, such as vacuum boosters, to meet specific and precise requirements.

Key Features and Benefits

Specifications

Applications

Dry screw vacuum pumps are suitable for a wide range of applications, including:

Why Choose Venlar Corporation?

Venlar Corporation has a long-standing reputation for delivering high-quality vacuum technology solutions. Our dry screw vacuum pumps are designed with cutting-edge technology to provide superior performance and reliability. With a focus on innovation and customer satisfaction, we ensure that our products meet the highest standards of quality and efficiency.

Contact Us

For more information about our dry screw vacuum pumps or to discuss your specific requirements, contact us today to learn more about our products, request a quote, or schedule a consultation with our experts.